Moisture measurement

Moisture measurement, one of the most difficult, but very important part, in the production process. And the more heterogeneous the product, the more difficult it becomes. In order to still be able to guarantee consistency, the determination of the moisture content starts with a reliable moisture sensor.

Quality requirements, economic value, energy consumption. Only a few words that could increase the importance of knowing the moisture content of your product. The best known existing inline systems are NEAR INFRA RED (NIR) and MICROWAVE. Beautiful systems that unfortunately can not be used in every application.

It seems so simple. A measuring system above or below the product and the correct value is measured. Our experience within the market, however, teaches us that the measured values are not always considered reliable and accurate. After analyzing the techniques used and the measurement results, different and above all explainable causes for the wrong measurement results can be given. Some of these reasons are explained on our website.

Save time

Go for higher quality

Stop endless calibrations

Our Moisture meters

In 2005 we developed a high-frequency moisture measuring system that is capable of measuring a thick shell of products (by that time: potting soil) on the inside of the cylinder. The high-frequency system covers most of the wall of the cylinder and has an penetration depth of about 8 centimeters. The covered volume is therefore much larger than the very fibrous and rough structure of the peat to be measured.

As a leading supplier of measuring equipment for measuring bulk density and moisture content of raw inhomogeneous bulk products, we continue to develop to meet market demand. Because we develop and produce ourselves, we are also able to adapt our equipment to your needs.

Moisturemeter l

Mobile Moisturemeter

Moisturemeter II

Moisturemeter IMP

Sensor types

Moisture sensor

IMT-20Lx

Moisture sensor

IMT-5Lx

Moisture sensor

IMP

Moisture sensor

IMP food grade

Satisfied users of INADCO equipment

Common practice of measurements

Many moisture sensors are available on the market. Nevertheless, the techniques used here can be reduced to 3 methods. In addition to a drying oven there is conduction, near infra red and micro waves. All fine measuring equipment but not always suitable for every industry.

Drying stove

Nowadays the most common way to determine the moisture content is to take a sample, place it in a stove and determine the weight loss after this sample has been heated for several hours, in some cases even 24 hours. The main disadvantages of this method are that you get the result only hours after production and that it is very labor-intensive. In most cases, the product has already left the premises or has already been processed at the moment that the results of the test become available. There is therefore less possibility to use the result for quality control or to prevent incorrect products from being delivered to your customer. Because the volume of the sample used in this method is relatively small, in most cases this is not representative of the total batch. When producing a product that contains various types of raw materials and is probably also wetted, practical tests have shown that such a small sample certainly does not represent production.

Near Infra Red

The most frequently used measurement method, Near Infra Red – short: NIR – gives a very bad result in many cases. This is because this method only measures the surface of the product flow and the measurement result is very vulnerable to changes in color, temperature and structure of the product. Moreover, the dust that is always present in excess in such processes disturbs the measurement. But the biggest problem is that the outside of the product is not representative of the internal moisture. This can happen because the product is not homogeneous, but also because the outside dries up when it is transported on the belt and it is more humid when it has rained.

Microwave or Conduction

The other known measuring system, the microwave sensor, has the advantage over Near Infra Red, which means that it not only measures the outside, but also measures a volume within the product flow. However, this method can not be used because the bulk density of the product changes from one moment to another in many cases. Some microwave sensors have a bulk density compensation, but they determine the bulk density by analyzing the high-frequency signal instead of weighing the product, divided by the volume. Moreover, the measured volume is in most cases far too small compared to the structure of the product.

LEGEND | |

Blue area | Measuring sensor (in this example a microwave sensor) |

Green area | Measuring area |

Brown area | Product |

White area | Air |

H2O (blue) | Water particle |

Calibration

Calibration is one of the most challenging and often the most labor intensive thing to do. And the more inhomogeneous the product or mixture is the higher the inaccuracy.

The mean reason for this is that the sample taken for the calibration isn’t large enough. Or the particle size of the product or mixture is larger than the sensor.

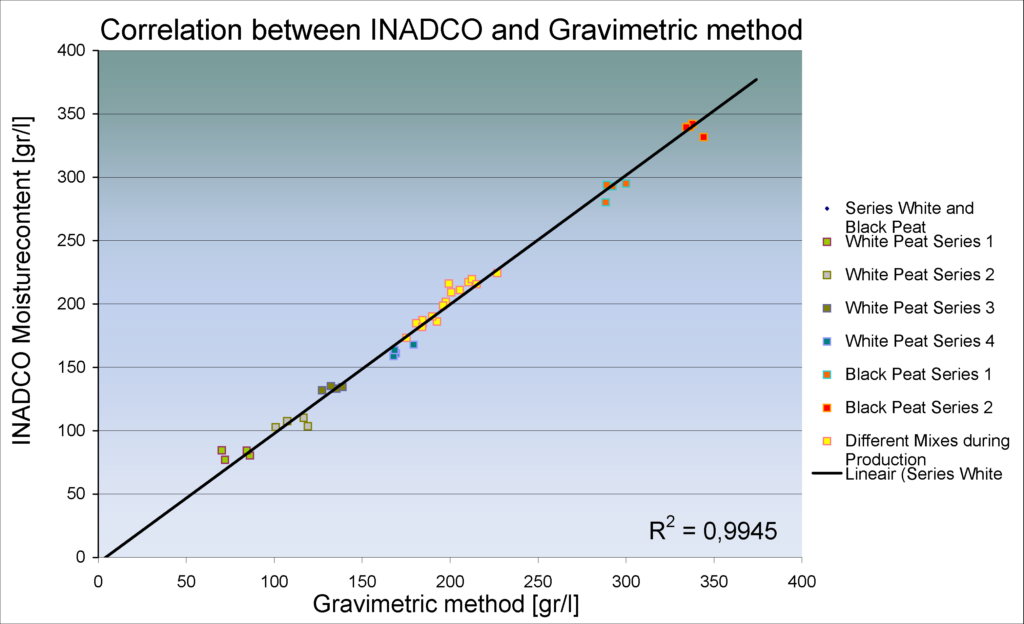

In comparison to the NIR or Microwave sensors our sensor is huge. Sometimes it can go up to a size of 1200x500mm. The size of our sensor combined with a correct way of sample taking for the calibration results in a abnormal high accuracy and just a few or even just one calibration line.